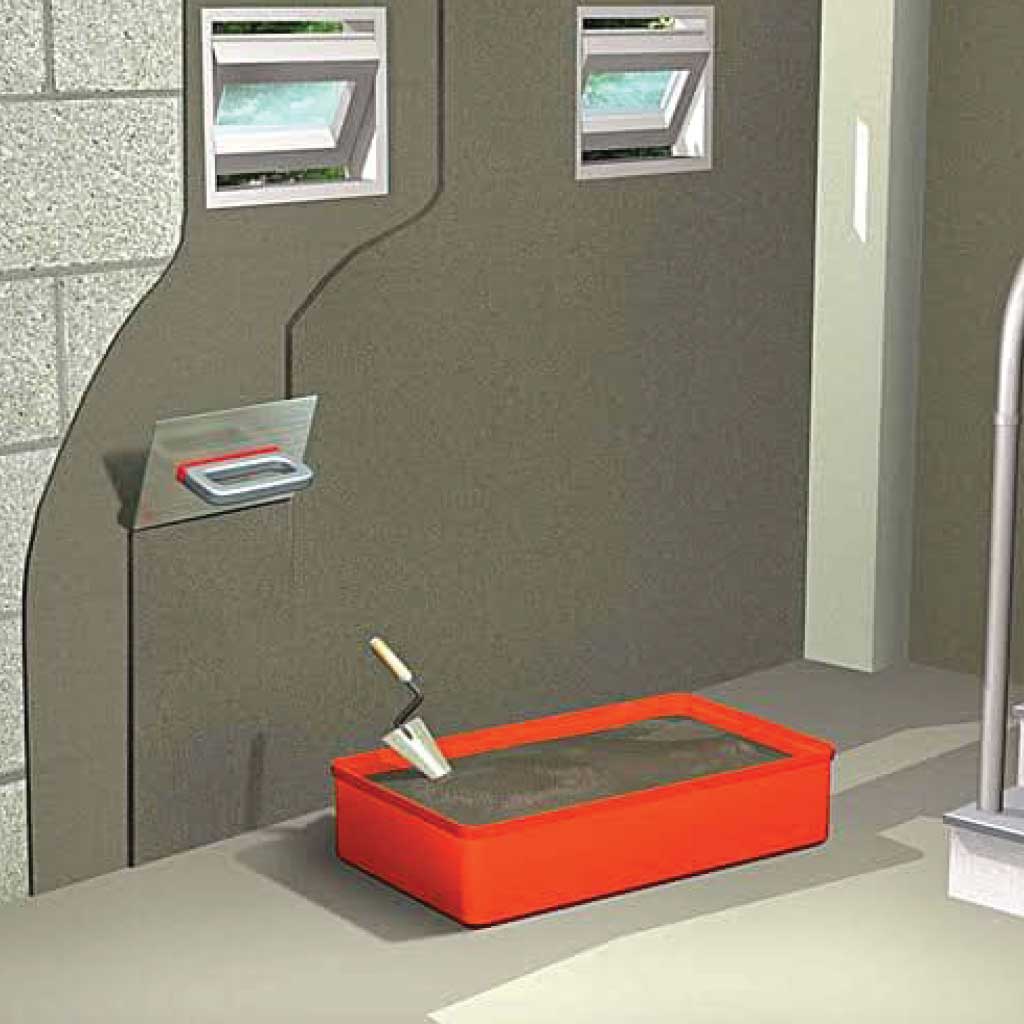

Insulate

insulating clay

It is a high-quality cement mortar ready to be used on all cement surfaces. It is made from a highly effective cement base to insulate moisture and heat. It is also used as an alternative to traditional clay directly on the block without a nail spray or coarse clay in one layer with a thickness of 3 mm to 7 cm without any cracks. It achieves good results. Excellent in softness and tropicalness.

Features:

(1) multi-colored.

(2) The surface purification is high, very smooth and free

from cracks

(3) Suitable for indoor and outdoor use.

4) High resistance to water and moisture.

(5) Weatherproof and easy to use.

(6) It is light in weight and can withstand large thicknesses

up to 7 cm without netting.

Technical information:

Applied at a temperature of 5 to 50 degrees Celsius.

Non-toxic, non-flammable and acid resistant.

Spray with water for 3 days, morning and evening.

The shelf life of the mixture after mixing is 60 minutes at a temperature of 25 degrees Celsius.

How to use:

The surface to be isolated is cleaned of oils, grease and dust, then 4 liters of water is added to a clean container and the contents of the bag are poured

Gradually and mix with an electric or hand mixer for 3 minutes

Coverage:

Duration of drying 1 is 1 day, and complete drying is 8 days,

And complete solidification 28 days.

Each 1 bag weighing 20 kg covers 2 square meters with a thickness of 1 cm

Or 7 meters with a thickness of 3 mm.

Packing: 20 kg bag

Note: You should not add any materials other than water.

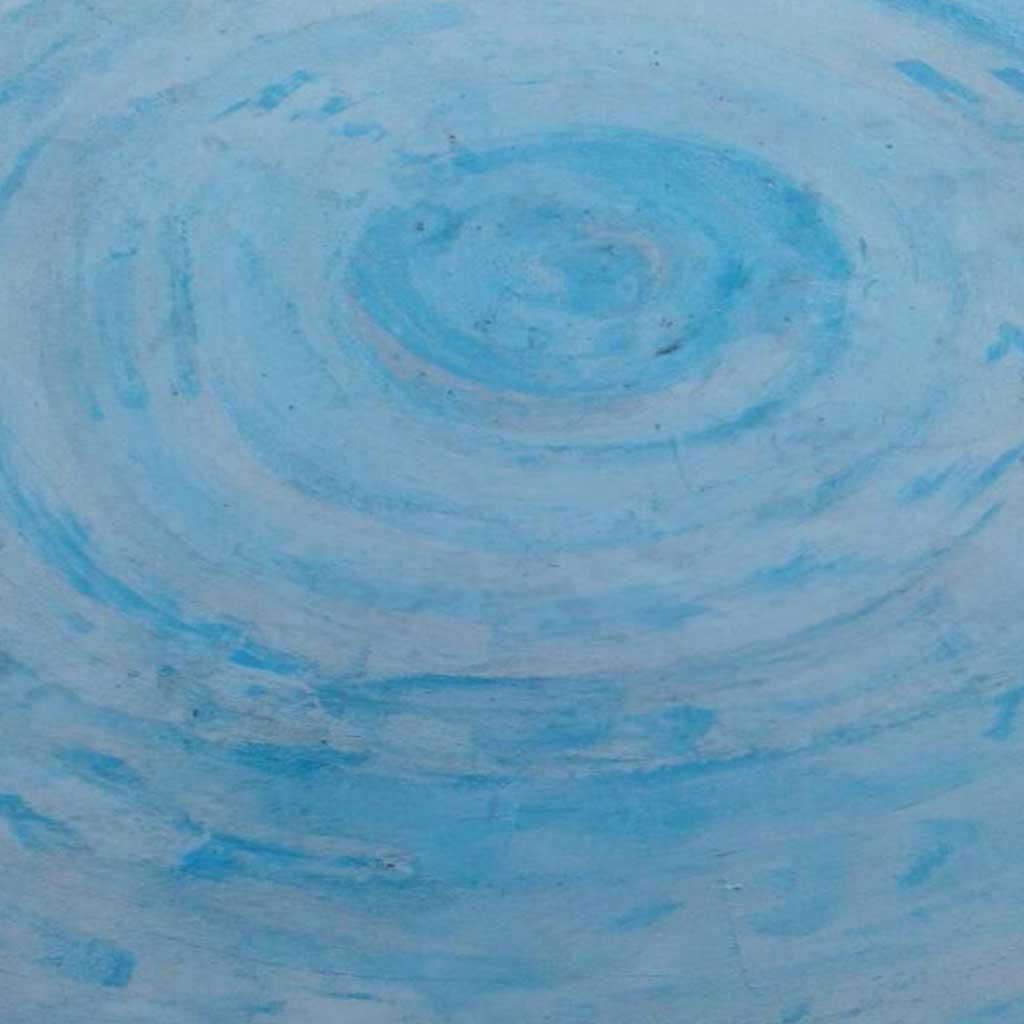

Cement insulation

Cement-acrylic paint consisting of two components, one of which is an acrylic latex liquid and the other a cured cement powder.

Pores relocate and become embedded in the surface.

Technical characteristics:

Density after mixing 25, 1.65 kg liter + 5%

Mixing ratio: Every 1 kg of liquid needs 2 kg of powder.

The shelf life of the mixture is 90 minutes.

The consumption rate is 2 kg per square meter, according to the smoothness of the surface.

How to use :

The surface is cleaned of impurities, oils and dust

Then wash off with water.

– In the event of surface defects, the surface shall be leveled

With a piece of grout.

– Add 5 liters of liquid in a clean bowl. The powder is gradually poured and mixed with an electric mixer for 3 minutes, then the mixture is left for 5 minutes, and then the application is done.

Then paint the surface with a brush, a roller, or by spraying.

The second face shall be painted after 2 hours at a temperature of 25 degrees.

– Clean the materials used with water before drying.

Packing:

Bag weighing 10 kg powder 5 liters liquid.

20 kg powder + 10 liters of liquid.

Product validity: 12 months

Note: No other materials should be added to the mixture.

Rubber insulation

It is a white, water-based paint that, after drying, gives a rubber insulating layer that has high resistance to water, non-leakage and weather fluctuations, and has flexibility and good adhesion strength with no cracking.

Features:

It can be painted directly on cement and concrete surfaces.

It has a high ability to cover the poetic cracks of being

Flexible rubber paint.

It has a high resistance to water and moisture insulation.

A friend of the environment.

How to use :

The surface must be cleaned of dust and impurities, and then painted

The first face with a roller or brush after diluting it by 30%

Leave it for 24 hours until the first face dries, then paint the face

The second without dilution in opposite directions

Leave between the first and second face 24 hours

Consumption rate:

Every 1 kg boil 10 square meters

Packaging: 16 kg drum.

Expiry date: one year from the date of production.

Floor putty

It consists of two compounds, one is powder and the other is liquid. It won the gold medal of the WIPO World Organization and the WIPO Global Certificate for the year 2017. It is a mixture of cured cement with liquid acrylic latex.

the description :

Floor putty is used as a material for negative and positive insulation

An alternative to marble and ceramic tiles, also used for walls

And the floors inside and out in many shapes and patterns

According to the customer’s desire.

Technical features:

(1) Density after mixing at a temperature of 25 – 180 + 5% kg per liter.

(2) The mixing ratio is 1 kg of liquid to which 2 kg of powder is added.

(3) Moisture proof.

(4) High adhesion on all surfaces.

(5) High abrasion resistance and hardness according

(4) High adhesion on all surfaces.

(5) High abrasion resistance and hardness according

Mohs 4 has a wear grade of 2 mm, tested at the Faculty of Civil Engineering at Damascus University.

(6) Quick to apply and dry.

(7) Water absorption is 2% after 24 hours and 0% after 28 days.

(8) Very soft and does not need watering.

How to use :

Pour 5 liters of white liquid into a clean bowl, then gradually add fine powder and mix with an electric mixer for 3 minutes until homogeneous, then leave for 5 minutes and then apply to the surface to be isolated by spatulas or by applying a roller, depending on the surface.

Each set weighs 15 buns, covering from 16 to 20 m, depending

Surface smoothness.

The initial drying time is 2 hours, and the complete dryness is 24 hours.

And complete solidification 28 days.

• The shelf life of the mixture after mixing is 90 minutes.

Packaging: 10 kg powder bag, 5 kg liquid bag

In a plastic pail.

Note: No other materials should be added to the mixture.

Shelf life: the product is 12 months.

Negative paint

It consists of two compounds, one of which is a soft, multi-colored powder, and the other is a liquid acrylic latex to protect buildings from the inside and outside, as well as the floors of printed floors, parking lots, and tile and sheet surfaces.

Technical features:

Colors are fixed.

High adhesion even on glass

High insulation from inside and outside.

Not affected by moisture.

High resistance to friction and corrosion.

Mix in the workplace.

The shelf life of the mixture is 60 minutes at a temperature of 25 degrees.

Technical Specifications :

1. Fine powder with liquid acrylic latex.

2. The mixing ratio for every 1 km of liquid requires 2 km of powder. . The amount of consumption for every 1 meter requires 0.6 kg of the ready mix. Weight volume 1.6 kg per liter 5

How to use :

(1) The surface shall be cleaned of dust and impurities and then washed with water.

(2) The liquid content is poured into a clean container. The powder is gradually added and mixed exclusively with an electric mixer until homogeneous. Then it is left for 5 minutes, and then the application is done by roller, brush, or spray.

Dehydration: initial dehydration 2 hours, complete dehydration 24 hours

And complete solidification 28 days at a temperature of 25

Packaging: 1 bag of 10 powder cakes with 1 bag of 5 kg of liquid

Inside a plastic bucket

Product validity: one year from the date of production.

It heals the inside

It is a ready-made powder that is mixed in the workplace and applied on surfaces as a slurry grout under tiles or on sheet ceilings. It consists of cement, siliceous sand, calcium carbonate, foaming chemical additives, and aster granules.

Features:

The volumetric weight of the mixture is 800 g per liter 1%.

Heat and sound insulation.

– Light weight equivalent to 30% of the weight of the cement mixture.

– Friction and scratchable.

– High water absorbency.

How to use :

Add 6 liters of water to a clean container and pour the contents of the bag gradually and mix with an electric mixer for 5 minutes, then apply.

Drought :

Initial dryness 48 hours, complete dryness 28 days.

Packing: 25 kg bag.

Shelf life: one year from the date of production.

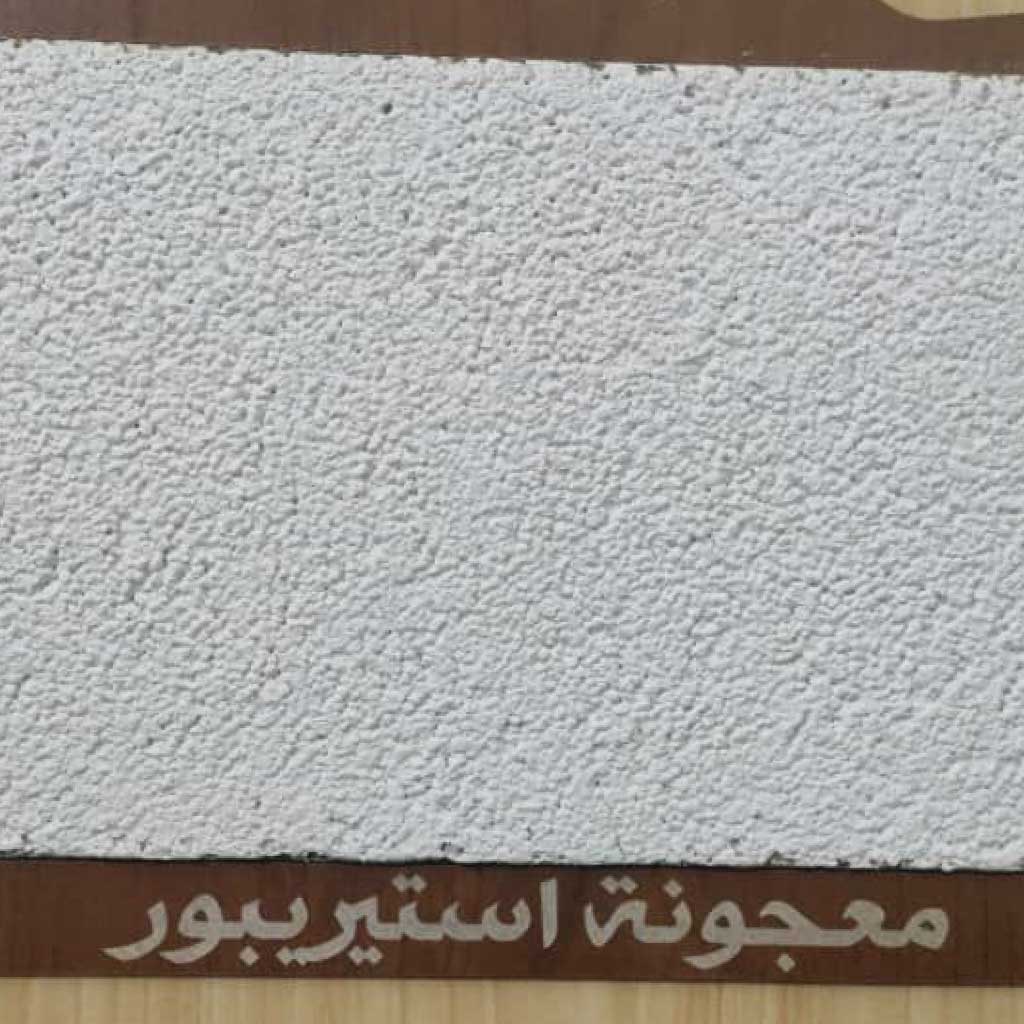

Ready-made Stereobur putty

It is a material that has heat and sound insulating properties, so that it helps to reduce heat leakage and transmission from outside the buildings to the inside in summer and vice versa in winter.

That is, most of this energy goes to get rid of heat

Acquired from walls and ceilings, hence the importance

Thermal insulation as it plays an important role in saving energy

Electricity consumed for adaptation purposes.

Technical and physical specifications:

1. High adhesion on all surfaces.

2. The possibility of isolating moisture.

3. Non-flammable.

4. Providing construction loads.

5. Protecting buildings from changing thermal bands.

6. The combustion rate is according to German specifications / A / DIN 4102 or 5, meaning that it achieved the highest non-combustibility rate.

7. Thermal insulation ratio / 0.0916W / MK / i.e. (Watt) / m – Kelvin).

8. Volumetric weight 65 g liter 2 +-%

How to use:

1. Clean the surfaces in a new way from dust and impurities

2. The paste is applied by spatula or trowel

0.5 cm thick.

3. Every 1 square meter needs 2.5 kg of ready putty

0.5 cm thick

Drying period:

Initial dryness 6 hours, complete dryness 24 hours

at a temperature of 25 °

Packing: pail of 14 liters of weight of 8 kg or bag of weight of 10 kg.

Expiry date: one year from the date of production.

Buffer powder

It is a soft, impermeable powder that is insoluble in water.

the use :

– It is used as a sealant for cement, by adding 5 kg of powder to the mixture

each bag of cement

– It is used for negative and positive insulation under the tiles

Underneath cleanliness.

How to use:

1. Add 5 kg of powder to the cement mixture, add to it and mix

On the dry with sand and gravel, then add water.

2. For insulation under the tiles or under the grout, mix the powder

With silica sand and applied with a thickness of 5 mm under the grout or tiles.

consumption amount:

Every 1 m needs 5 kg of powder on the surface to be isolated.

Every 5 kg of powder is added to 1 bag of cement weighing 200 kg of the mixture.

Packing:

15 kg bag.

Shelf life: unlimited.